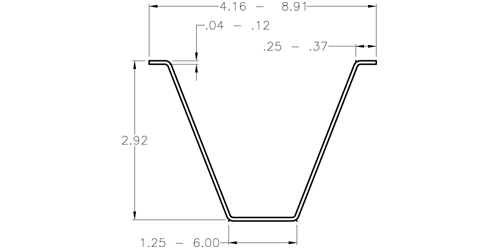

Hat Channel Sizes Chart

The Web size is 1-14.

Hat channel sizes chart. STEEL FRAMING INDUSTRY ASSOCIATION. For joists 600 mm 24 oc. In concrete wall applications furring channel is installed vertically to the wall surface using concrete nails or power-driven fasteners.

NNestable hats and channels can be joined without a separate clip angle increasing speed and reducing cost of on-site fabrication. Minimum base metal thick-ness represents 95 of the design thickness. Hat Channels are often used in framing components used for ceilings and masonry walls.

3 Bearing length 075-inches. The deeper the channel the higher the capacity it can hold. U Channel Sections F Furring Channel Sections L Angle or L-header MATERIAL THICKNESS.

Length - 12-0 and 20-0. In addition to being more corrosion resistant and easier to form than multipurpose 6061 aluminum these hat channels have flanges that make them easy to mount on flat surfaces. Hat Channelsare fabricated in 12 78 1-12 depth from 25 gauge to 14 gauge steel.

The most common hat channel sizes typically range from a ⅞ furring channel to a 1 ½ furring channel. Furring Channel may be used for furring masonry walls and ceiling assemblies or in any other typical wall furring or cross-furring or framing application. 1 Allowable ceiling spans are based on effective properties.

Plaster install resilient channels perpendicular to framing and spaced 600 mm 24 oc. Furring channel is available in 18 27 30 and 43 mil thicknesses 25-18ga. Bearing surface is 1-14ざ.